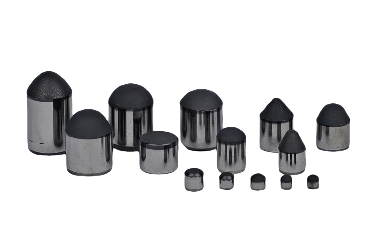

Diamond Composite Insert

Diamond Composite Insert

Diamond composite insert are sintered by carbide matrix and diamond powder at high temperature and high pressure. Adopting a multi-layer structure, the product has extremely high wear resistance while also possessing high impact resistance. Meanwhile, due to the excellent thermal conductivity and wear resistance of diamond, the thermal fatigue failure in the rock breaking process can be greatly reduced during the application. Used on rock breaking tools for oil drilling and mining, it can effectively improve the ability and efficiency of the tool to drill into abrasive formations and extend the service life of the product.

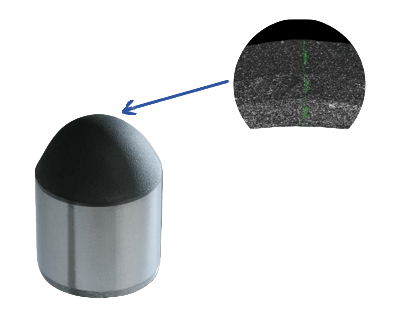

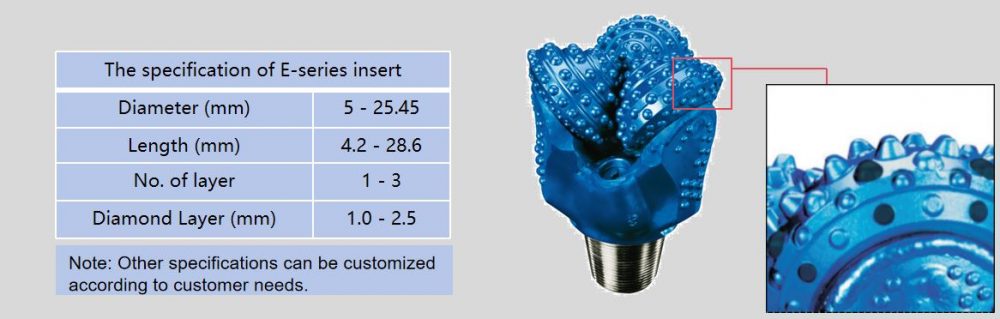

E series: Diamond composite insert for tricone bit

It has excellent impact resistance, thermal conductivity, and wear resistance, and has a longer service life and higher rock breaking efficiency compared to traditional cemented carbide. The product specifications are complete, with different shapes, including flat insert, conical insert, spherical insert and wedge-shaped insert, which can be applied to the main cutting row of the cone and the gage row and diameter protection position of the bit.

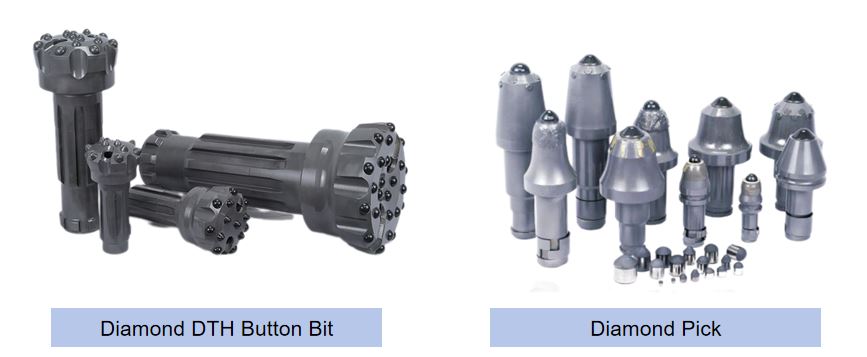

DY series: Diamond composite insert for mining tools

It has excellent impact resistance, thermal conductivity, and wear resistance. Compared with traditional cemented carbide, it has advantages of long service life, high rock breaking efficiency, and low comprehensive usage cost. It can be used for rock breaking tools such as DTH hammers and picks.

Mining Tool with Diamond Insert of DY Series

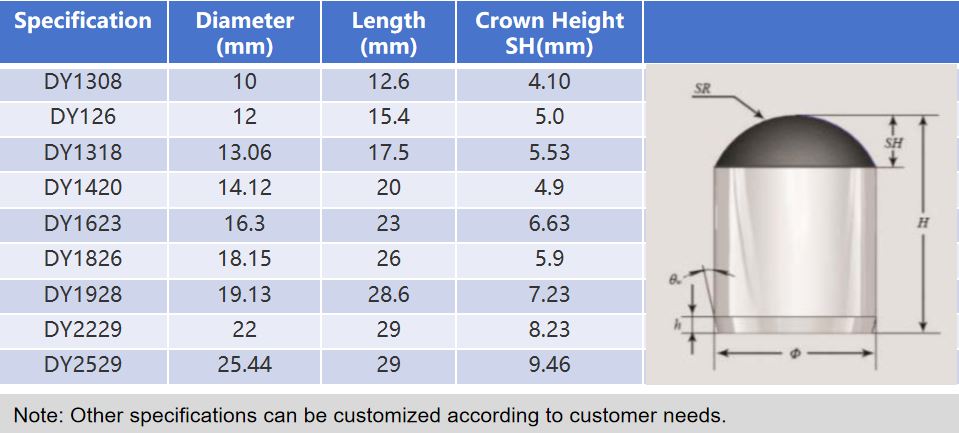

Common sizes for DY series

Main Office

16 Floor,Kunyu International Center, Guanshan Street, East lake High-tech development zone, Wuhan, Hubei

Contact Us

Tel.: (+86)177 0276 3726 Whatsapp: +86 177 0276 3726 Email: daniel@zhiteng-tech.com zhiteng_tech@outlook.com