PDC Cutter

PDC Cutter

Polycrystalline diamond compact (PDC) is sintered by cemented carbide matrix and diamond powder at high temperature and high pressure. It has the characteristics of high hardness and good wear resistance, and is widely used in oil drilling, geological exploration, mine drilling and mechanical processing.

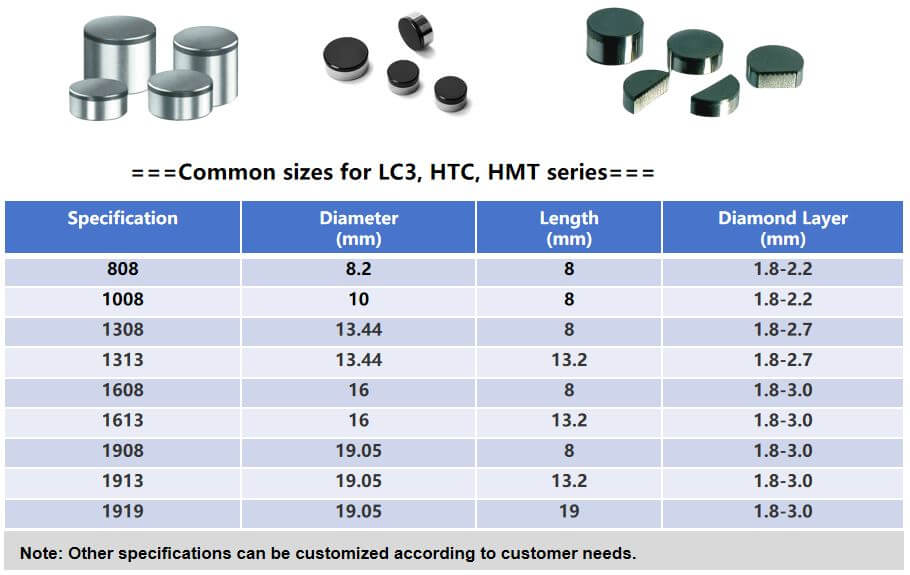

The diamond compact provided by the company adopts specially customized raw material formulas and unique high-temperature and high-pressure processes, supplemented by finite element analysis, temperature measurement, pressure measurement and other technologies, combined with various performance evaluation methods, the wear resistance, impact resistance and thermal stability of the products are specially designed to meet the needs of drilling soft to extremely hard formations, crossing hard interlayers and other complex formations. The company has a complete product range. Three flat cutter series – LC3, HTC, HMT, and a non flat cutter series – TR2 are formed for different application markets and drill bit positions.

LC3 series

(1) Through finite element simulation analysis, a unique interface structure is adopted to improve the stress distribution state and effectively avoid diamond layer peeling.

(2) Using a single-layer diamond structure, the product has excellent wear resistance.

(3) Optimize the vacuum high-temperature treatment curve to improve the wear resistance and impact resistance of the product.

HTC series

(1) Select high-quality diamond micro powder.

(2) Using a double-layer diamond structure, the surface of the product has excellent wear resistance, the transition layer has excellent impact resistance, and the overall performance is excellent.

(3) Adopting a unique high pressure structure to improve the self sharpness of the product.

HMT series

(1) Optimize the formula of diamond micro powder.

(2) By adopting a unique interface structure and diamond double-layer structure, the product has excellent wear resistance, impact resistance and reliability, effectively improving its adaptability and service life in complex working conditions.

(3) Adopting ultra-high pressure technology and optimizing the HPHT process, the comprehensive performance of the product is further improved.

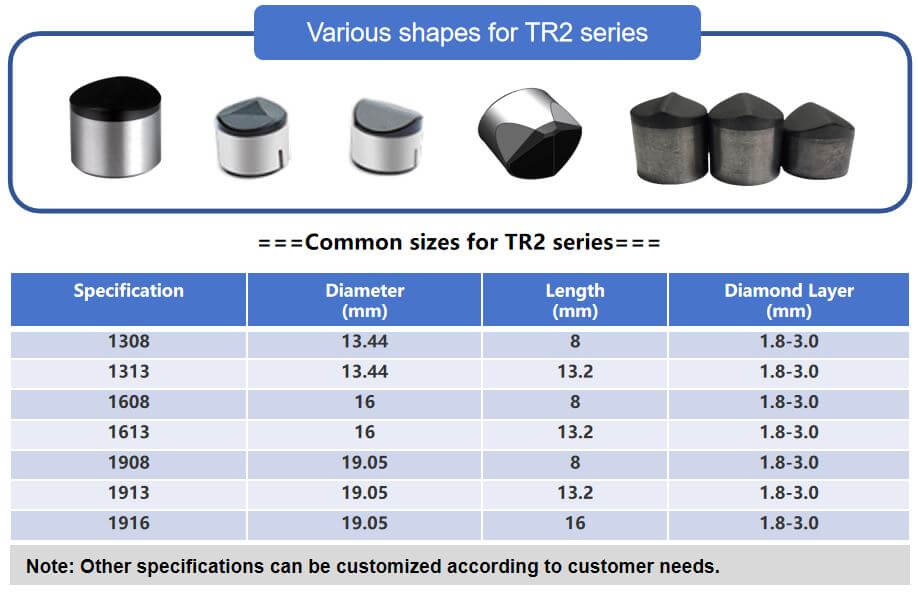

TR2 series

(1) TR2 is a non planar cutter series, called Structural Cutter, with various surface shapes such as triangular cutter, axe shaped cutter, conical cutter and conical spherical shaped cutter, etc.

(2) Structural cutters are a significant breakthrough in the field of oil and gas PDC cutter, completely changing the traditional single design concept, optimizing the adaptability of drill bits to various downhole working conditions, greatly improving drilling speed, and providing practical and feasible solutions for drilling complex formations.

Main Office

16 Floor,Kunyu International Center, Guanshan Street, East lake High-tech development zone, Wuhan, Hubei

Contact Us

Tel.: (+86)177 0276 3726 Whatsapp: +86 177 0276 3726 Email: daniel@zhiteng-tech.com zhiteng_tech@outlook.com