Pick

Pick

Cutting picks are very important parts of construction machinery, which are tools used for cutting, excavating, and crushing hard materials.

From the perspective of industry and usage, cutting teeth can be divided into two major categories: mining pick and engineering pick. Mining picks are cutting tools used in coal mines. Engineering cutters are mainly used in highway and construction projects.

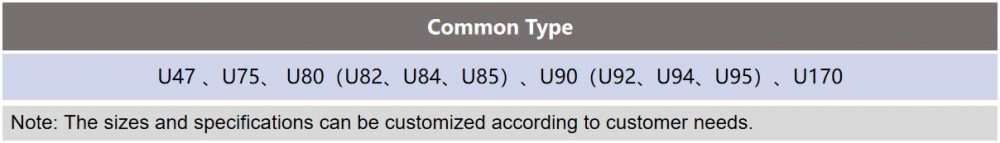

Pick for coal mining machine

The coal cutter pick is a cutting tool in the underground coal mining machinery, installed on the coal mining machine drum together with the tooth sleeve and tooth socket, and it is one of the vulnerable parts of coal dropping. Its performance directly affects the production capacity of coal mining machinery, power consumption, working stability, and the service life of other related important components. We focus on the research and development as well as innovation of hard rock cutting pick technology, our products have been working in harsh environments such as hard rock tunnels and full-rock sections with a hardness above F12 for a long time. We promise our picks have good wear resistance, long service life, strong penetration, high coal dropping efficiency, and high impact resistance.

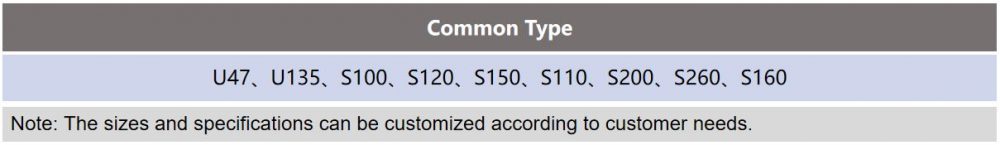

Pick for tunnel boring machine

The cutting picks of the tunneling machine are the main cutting tools on the cutting head of the tunneling machine. They are installed on the cutting head in conjunction with the tooth seat and are one of the vulnerable parts for tunnel excavation.. We have adopted a stepped radial body design, standard tooth shoulder design, and insulation design, which significantly enhance the strength and wear resistance of the picks, as well as extend the service life of the products and ensure safety.

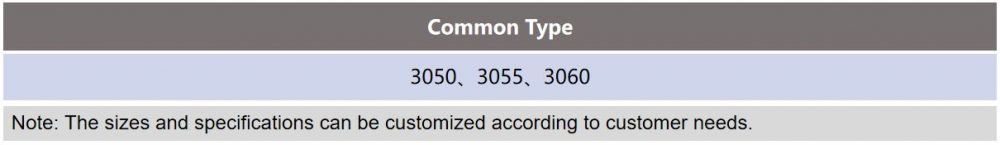

Rotary Drilling Pick

The series of our rotary drilling picks are 3050, 3055, and 3060, which are suitable for both heavy-duty and extra-heavy-duty working conditions. Our picks belong to the hard rock grade, featuring high wear resistance, exceptional penetration power, and crushing efficiency, enabling efficient acceleration of the engineering progress.

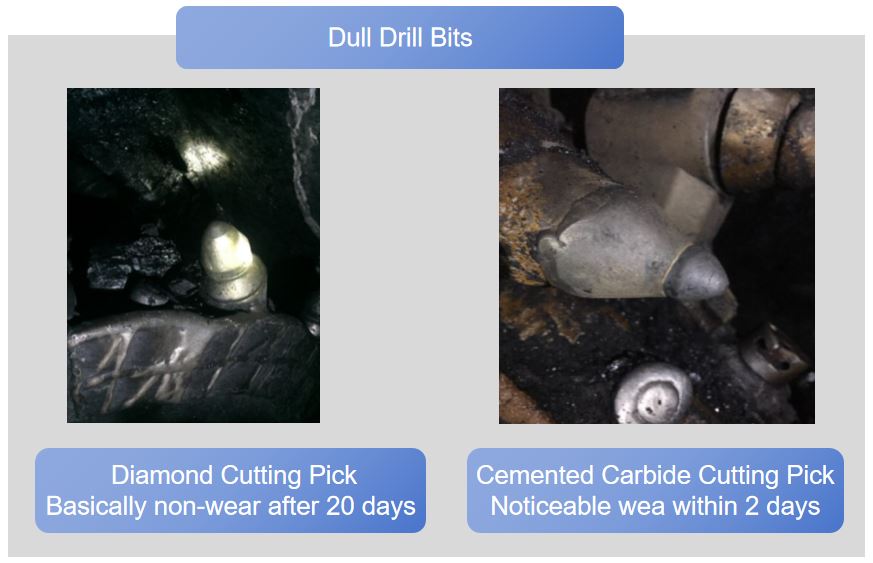

Innovative Product: Cutting Pick with Diamond Composite Insert

Usually, the cutting picks are equipped with hard alloy cutting heads, which are used for cutting, excavating, and crushing various hard materials. The wear and tear of alloy cutting heads are the main factors causing damage to cutting picks. In order to extend the service life of the cutting picks and improve their working efficiency, we creatively use diamond composite inserts as alloy heads instead of the tungsten carbide material, supplemented by further strengthening of various parts of the pick body, so as to make the cutting picks have superior wear resistance, longer service life, higher construction efficiency and cost-effectiveness, especially for difficult to hit rocky coal seams.

Comparison of on-site use of two types of picks

(1) The footage is increased by more than 33% and the pick consumption is reduced by 80%. (2) Exhibit strong wear resistance and impact resistance, improving the efficiency of the product during operatio (3) The service life has increased and the consumption has significantly decreased, reducing a large amount of non working time for inspection, maintenance, and replacement of cutting picks, while also reducing the labor intensity of workers.

Main Office

16 Floor,Kunyu International Center, Guanshan Street, East lake High-tech development zone, Wuhan, Hubei

Contact Us

Tel.: (+86)177 0276 3726 Whatsapp: +86 177 0276 3726 Email: daniel@zhiteng-tech.com zhiteng_tech@outlook.com